EX (max. density: 2.4)

POLYex

Intermediate Bulk Container

POLYex IBC

Versions & accessories

POLYex IBCs are UN tested and approved for filling with flammable liquids and use in EX zones 1 and 2.

- Conductive multi-layer technology

- Safe against electrostatic ignition hazards according to IEC TS 60079-32-1:2013 and TRGS 727:2016

- Can be used with liquids of explosion group IIA

- Closed conductive valve body

- Easily distinguished UN and NON-UN IBC

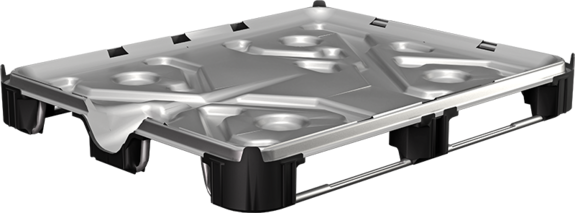

Dimensions

The following dimensions are standardised IBCs for filling materials up to a density of 1.6 Rho

volumes | length | width | height |

|---|---|---|---|

1000 | 1200 | 1000 | 1163 |

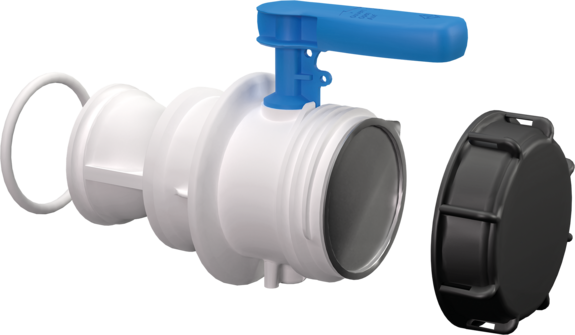

Valves

We offer integrated or replaceable valves.

Volumes | DN 50 mm | DN 80 mm |

|---|---|---|

1000 |

Lid

Volumes | DN 150 mm | DN 225 mm |

|---|---|---|

1000 |

We would be pleased to provide you with non-binding advice on your solution from WERIT

FAQ

Frequently Asked Questions

HDPE is a robust and durable plastic which, in case of our IBC containers, is translucent and protects the content against UV radiation. Our IBC accessories also comprise this special material. HDPE is generated by the industrial polymerisation of ethane. At the beginning, this raw material was milky and waxy. However, today it has developed to an innovative thermoplastic plastic with ideal deformation properties and can be adjusted optimally to all specific requirements by the addition of additives. The HDPE that we use is dimensionally stable at temperatures from -40 to +70 °C and resistant against most alkalis, acids and chemicals.

An interesting fact at the end: HDPE has already been used commercially since 1957 for cable insulation, piping systems and packaging material.

The dimension for the filling opening is the same for all three product lines. The ECOline IBC (non UN), TOPline IBC (UN) as well as the POLYex IBC containers are equipped either with an NW 150 or NW 225 filling opening with screw lid and an optional venting. The ECOline IBC (non UN) is additionally available with an NW 400 filling opening with clamping ring lid.

All of our IBC containers are equipped with a NW 50 or NW 80 discharge valve which is integrated or replaceable.

Naturally. Our containers are suitable for almost all liquids - why shouldn't it also be used as a rain tank? The (food product) industry is already also using water tanks today.