Packagings from WERIT for chemicals, pharmaceuticals and cosmetics

Storage, stacking and transporting ... and that being clean, safe and efficient. Chemicals belong to the most frequently transported assets at all. Transportation takes place in great quantities on the road, rails or on water. In doing so, transportation is not only carried out by the chemical industry, but trade companies of other industry sectors also transport amounts of chemical substances and mixtures that must not be underestimated.

For the transportation of so-called hazardous goods, in Germany, the EU and even world-wide, there are a multitude of laws, regulations and guidelines that, in particular ensure the adherence of special transport and safety measures for the protection of humans, animals and the environment. Typical hazardous goods are, for example acids, brine, flammable paints, gases or even pesticides and insecticides.

The best products for transport and storage

The transportation of sensitive goods places high demands and a suitable packaging. We know the special features of the industry and are familiar with the high hygiene requirements in the pharmaceutical and cosmetics industry as well as the extensive safety guidelines in the chemical industry. Other factors are the impacts of the climate change, capacity bottlenecks, outdated infrastructure and digitisation. Pharmaceutical and chemical logistic companies are faced with real challenges as they are ruled by the global supply chains into which the suppliers of raw materials and pre-products as well as the sales and distribution of the finished products are integrated. Reusable transport packagings, hygiene pallets or IBCs are especially developed for this purpose, certified and fulfil these technical and hygienic requirements.

The Clean Box from Bio-Circle

The Bio-Circle Surface Technology GmbH is a company with main office in Gütersloh, North Rhine-Westphalia operating internationally. The two-man company founded in 1985 by graduate engineers Ulrich and Manfred Berens stands for more than 30 years of development, production and the sales of chemical and biotechnological products around surface technologies.

For the area of mobile part washing devices "CLEAN BOX ", Bio-Circle uses the WERIT DSB-N stack and nest containers. The different variants of the CLEAN BOX are suitable for the effective pre-cleaning of small but also large and heavy manageable parts. That renders this concept usable in many plant and production areas such as, in maintenance, mechanical or in industrial construction. The CLEAN BOXs are characterised in particular by their circulatory system, their simple handling and the use of low-temperature cleaning.

Safety for hazardous goods

Depending on the properties and safety requirements, hazardous goods must be packaged in different ways. Drums, canisters and IBCs must comply with the internationally established safety stipulations and be subject for the special use of regular examinations by the responsible authorities. In doing so, comprehensive load tests are carried out. Despite the high safety precautions, accidents during the transportation of hazardous goods occur over and over again.

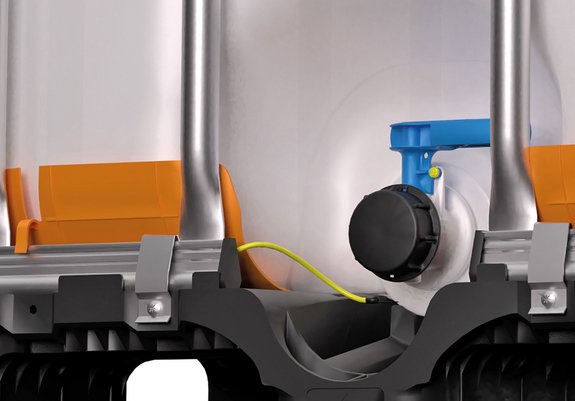

As a response to this, we have developed the UN certified TOPline IBC, which is available with approval up to a material density of 2.4 kg/litre. Liquid goods such as brine, acids, paint or special solutions are therefore safely packaged. With this, WERIT has set a benchmark for the German market. With the multi-layer POLYex IBC, we have developed a container that cannot charge electrostatically when filling, emptying and handling. The conductive outer layer of the inside container, an integrated, conductive integrated valve, a two-sided bolted earthing cable and an earthing plate on the pallet prevents the ignition of flammable fluids by discharging.

Earthing cable

Corner protector

Pallet earthing

Plastic pallets for the chemical industry

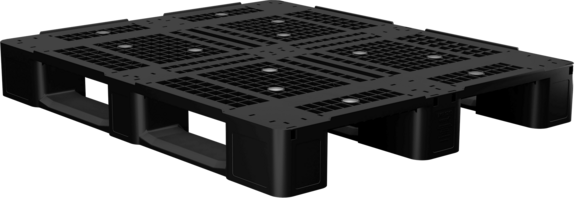

For the distribution and storage of medium-heavy goods in the chemical industry, WERIT offers an economical alternative with the IKP 1213 and 1215, as both plastic pallets are made of pure HDPE regenerated material.

They are robust, dimensionally stable and durable plastic pallets in the industrial size of 1200 x 1000mm. With either 3 or 5 runners, they’re particularly characterised by their many variation alternatives and areas of application in the chemical industry, especially in regard to the dispatch of goods and different types of packaging; such as: containers, bags, octabins, barrels or cardboard boxes. The use of the plastic pallets IKP1213 and IKP1215 can be utilised, as the risk of damage to the load is minimised and the flow of goods can take place without any disruption.

In addition to the economic reasons for using plastic pallets, it is also worth taking a look at the occupational safety of the employees who work with the load carrying every day. Here, the safe, light and practical plastic pallets of the IKP series offer clear advantages over wooden pallets. Compared to a wooden pallet weighing over 20 kg, the IKP1213 or IKP1215 are considerably lighter at 14 and 15kg respectively.

Also, due to the material used, injuries caused by splinters or nails no longer exist.

Unlike wood, a plastic pallet does not attract moisture. The resulting constant weight and low deflection values of the pallet make it a perfect companion in all areas of logistics in the chemical industry.

Features:

- Available as 3 skid IKP1213 or 5 skid IKP1215

- Low dead weight of only 14 or 15kg

- Robust and economical for heavy-duty use

- Versatile and flexible for current and future logistics requirements

- Both sides of all runners are inclined for optimum use with industrial trucks

Options:

- Up to 6 steel profiles, for a load capacity of up to 1,250kg in high rack

- Anti-slip edge options:

- No anti-slip edge

- 7mm non-slip edge

- 22mm non-slip edge

- Up to 12 anti-slip plugs from top to bottom